Installation Methods

An important aspect of purchasing a sign is the planning and preparation of how it will be installed. We offer several different installation and mounting methods for our LED signs and sign cabinets. Unless noted, each method is available for our 7" and 10" extrusions.

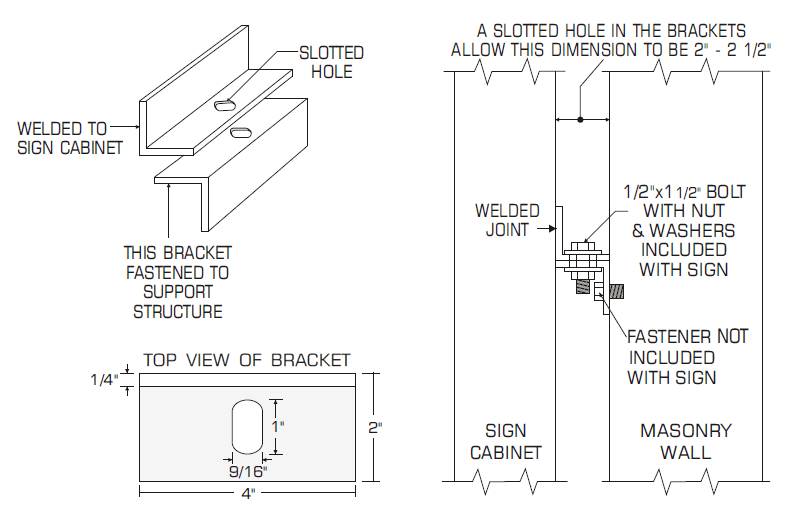

Side and Bottom Brackets

Four brackets are welded to the cabinet, and have slotted 9/16" holes in the center. These align with four other included brackets that are attached to the mounting surface. Brackets are located 10" in from each side and at the center of the cabinet height.

Side Brackets

Four brackets are welded to the cabinet, and have slotted 9/16" holes in the center. These align with four other included brackets that are attached to the mounting surface. Brackets are located at 25% and 75% of the cabinet height on each side.

Wall Gussets

Four 6" x 6" x 1/8" aluminum gussets (triangles) are welded to the inside corners at the back of the cabinet. These gussets are then drilled through to attach the cabinet to a surface with your mounting hardware. Available with the 4" extrusion.

Vertical Angles

Two 2" x 2" x 1/4" aluminum angle brackets are welded to each side of the cabinet. These brackets are then drilled through to attach the cabinet to a surface with your mounting hardware. For cabinets with sign faces, faces are removed from the top or bottom.

Horizontal Angles

Two 2" x 2" x 1/4" aluminum angle brackets are welded to the top and bottom of the cabinet. These brackets are then drilled through to attach the cabinet to a surface with your mounting hardware. For cabinets with sign faces, faces are removed from the side.

Side Holes

Four 9/16" diameter holes are provided in the sides of the cabinet. The holes are used to attach the cabinet to a surface with your mounting hardware. Holes are located at 25% and 75% of the cabinet height on each side.

Side and Bottom Holes

Four 9/16" diameter holes are provided in the bottom and sides of the cabinet. The holes are used to attach the cabinet to a surface with your mounting hardware. Holes are located 10" in from each side and at the center of the cabinet height.

Holes and Brackets

Two 9/16" diameter holes are provided on each side at the center of the cabinet height. The holes are used to attach the cabinet to a surface with your mounting hardware. Two brackets are welded to the bottom of the cabinet, and have slotted 9/16" holes in the center. These align with two other included brackets that are attached to the mounting surface.

Single Thru Pole

Pole is centered on the cabinet and of a length of your choosing. 7" extrusion cabinets require a 4" or 5" wide pole, while 10" extrusion cabinets require a 4", 5" or 6" wide pole. With this method, any lamps must be vertical within the cabinet.

Double Thru Pole

Poles will be at 25% and 75% of cabinet width, and of a length of your choosing. 7" extrusion cabinets require 4" or 5" wide poles, while 10" extrusion cabinets require 4", 5" or 6" wide poles. With this method, any lamps must be vertical within the cabinet, and may result in darker areas of the sign face depending on pole width.

Double Thru Pole with Pole Cover

The same as our double thru pole method, but with a sheet of welded aluminum attached to both sides. Provides a more finished appearance, and allows for a vinyl street address or other information on the mount.Bracket Installation

For installation methods that include slotted brackets, these are matched with other included brackets that you fasten to the mounting structure. Fasteners to the mounting surface are not included.

To prevent potential difficulties, we strongly encourage you not to build the masonry structure until you have received the sign and have verified all measurements and properly aligned all hardware.

Mounting & Finishing Package

Our sign dealers have the ultimate flexibility in designing their sign package. Our complete sign, bracket-mounted and single-sided wall-mounted signs come with everything you need for a typical project, including aluminum or steel angles for wall mounting. We also provide an optional Mounting & Finishing package that includes:

- Powder-coated aluminum perforated filler panel to give double-sided LED cabinets a single cabinet look.

- Powder-coated aluminum perforated rear panel to complete the exposed back of a single-sided LED cabinet.

- Horizontal or vertical aluminum angle welded to the back of LED cabinets for pole or special mounting considerations.

Please select this option if you require one or all of these components in your sign package.

Become a Dealer

Stewart Signs Wholesale sells products exclusively to Authorized Dealer Partners.